The pharmaceutical industry is undergoing massive transformation—driven by rising global demand, evolving healthcare models, stricter compliance requirements, and the growing need for supply chain resilience. In this environment, companies can no longer rely on legacy tools or reactive planning processes.

To remain competitive and patient-focused, pharmaceutical supply chains must be intelligent, agile, and integrated. Yet several critical challenges continue to impact performance.

1. Unpredictable and Volatile Demand

The pharma industry deals with up to 40% forecast error on average, according to McKinsey, due to a wide array of variables—regulatory approvals, patent cliffs, outbreaks (like COVID-19 or RSV), and shifting prescription trends.

2. Long Lead Times and Limited Supply Flexibility

Manufacturing lead times in pharma are significantly longer than in other industries—ranging from 2 to 12 months, depending on complexity, validation, and quality assurance processes.

3. Stringent Compliance and Regulatory Pressures

Pharmaceutical products are governed by complex, country-specific regulations such as FDA’s Drug Supply Chain Security Act (DSCSA) and EU Falsified Medicines Directive (FMD), requiring full batch traceability and serialization.

4. Cold Chain and Shelf-Life Constraints

Roughly 70% of top-selling pharma products require temperature-controlled transportation and storage. Failure in cold chain logistics can render drugs ineffective or dangerous.

5. Fragmented Planning Across Functions and Partners

Pharma supply chains typically involve dozens of partners, including CMOs (Contract Manufacturing Organizations), CROs (Contract Research Organizations), packaging suppliers, and third-party logistics providers.

SAP Integrated Business Planning (IBP) offers a powerful, cloud-based platform that helps pharma companies orchestrate supply chain planning in a connected, responsive, and patient-centric manner.

1. Advanced Demand Planning and Sensing

SAP IBP enhances forecast accuracy by leveraging:

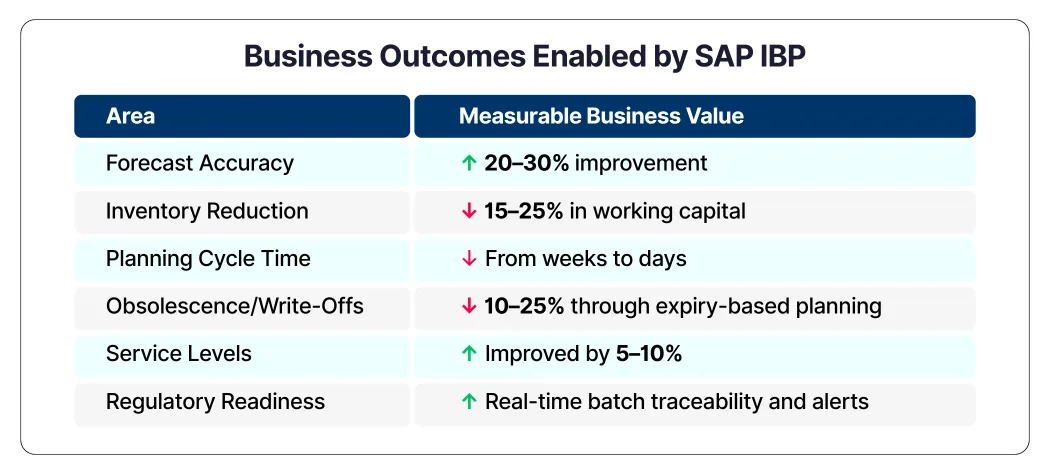

It enables demand sensing at daily/weekly levels, helping respond to dynamic market conditions. Companies using SAP IBP have reported up to 20–30% improvement in forecast accuracy and reduced safety stock requirements by 10–15%.

2. Agile Supply Planning with Constraint Awareness

IBP’s finite capacity planning models account for:

Scenario-based simulations allow planners to evaluate multiple supply strategies, improving responsiveness to disruptions like raw material shortages or manufacturing outages.

3. Compliance Through Visibility and Traceability

SAP IBP integrates with systems like SAP S/4HANA and SAP Digital Manufacturing to provide:

This helps pharma companies minimize compliance risks and respond quickly to regulatory inspections or audits.

4. Shelf-Life and Cold Chain Planning

IBP can incorporate shelf-life constraints directly into supply and inventory plans. Key features include:

Companies have reduced inventory obsolescence by up to 25% using SAP IBP’s shelf-life functionality.

5. Unified Platform for End-to-End Planning

SAP IBP supports S&OP, demand, supply, and inventory planning on a single platform. It enables:

This integrated view significantly improves decision-making speed and alignment—cutting planning cycles from weeks to just a few days.

The pharmaceutical industry faces a uniquely complex and high-stakes supply chain environment, where disruptions can directly impact patient health and business continuity. In this context, traditional planning methods are no longer sufficient to manage the increasing volatility, regulatory demands, and operational constraints.

SAP Integrated Business Planning (IBP) offers a comprehensive, real-time platform that enables pharmaceutical companies to move from reactive decision-making to proactive, data-driven planning. By aligning demand, supply, inventory, and compliance considerations on a unified platform, SAP IBP empowers organizations to improve forecast accuracy, enhance agility, reduce costs, and ensure consistent product availability.

At ArchLynk, we combine deep SAP supply chain expertise with a value-first approach to help pharma companies unlock smarter, compliant, and connected planning—delivering measurable outcomes and transforming complexity into opportunity.

Looking to make your pharma supply chain future-ready? Connect with our experts today.