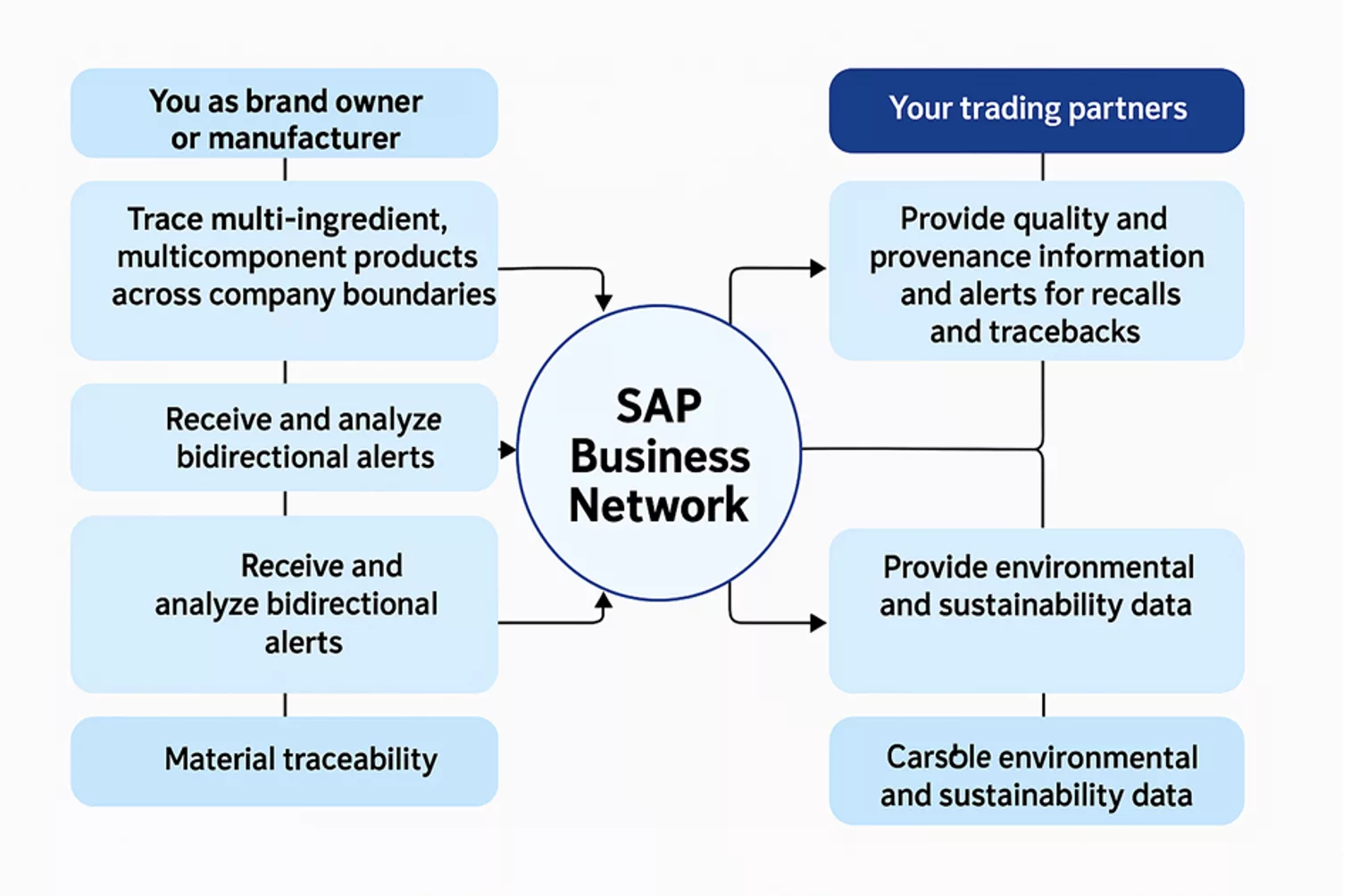

SAP Business Network for Materials Traceability helps organizations to gain better visibility into material movement across supply chains. By leveraging advanced technologies such as IoT and blockchain, it enhances tracking capabilities, supports regulatory compliance, and improves operational efficiency. This solution is especially beneficial for industries that require strict adherence to quality standards and regulations, including pharmaceuticals, food, and automotive sectors.

In today's world, as individuals, we have the right to know what we buy, whether it’s materials or food, and to understand the sources of raw materials ethically and transparently. Companies also need to build trust in what they sell. In today’s globalized supply chains, businesses face increasing challenges related to transparency, compliance, and efficiency. Material traceability has become a critical necessity, enabling companies to track materials from their origin to the final product. According to SAP, material traceability helps organizations minimize risks, ensure compliance, and improve decision-making by providing real-time data across the supply chain

Real-World Example of Material Traceability

Industry Focus: Food safety & quality assurance.

Use Case: A Chocolate manufacturer sourcing cocoa from multiple farms.

SAP BN4L - Material Traceability includes several key features designed to enhance supply chain visibility and compliance:

SAP continues to enhance Material Traceability with new updates that further improve tracking, automation, and collaboration capabilities.

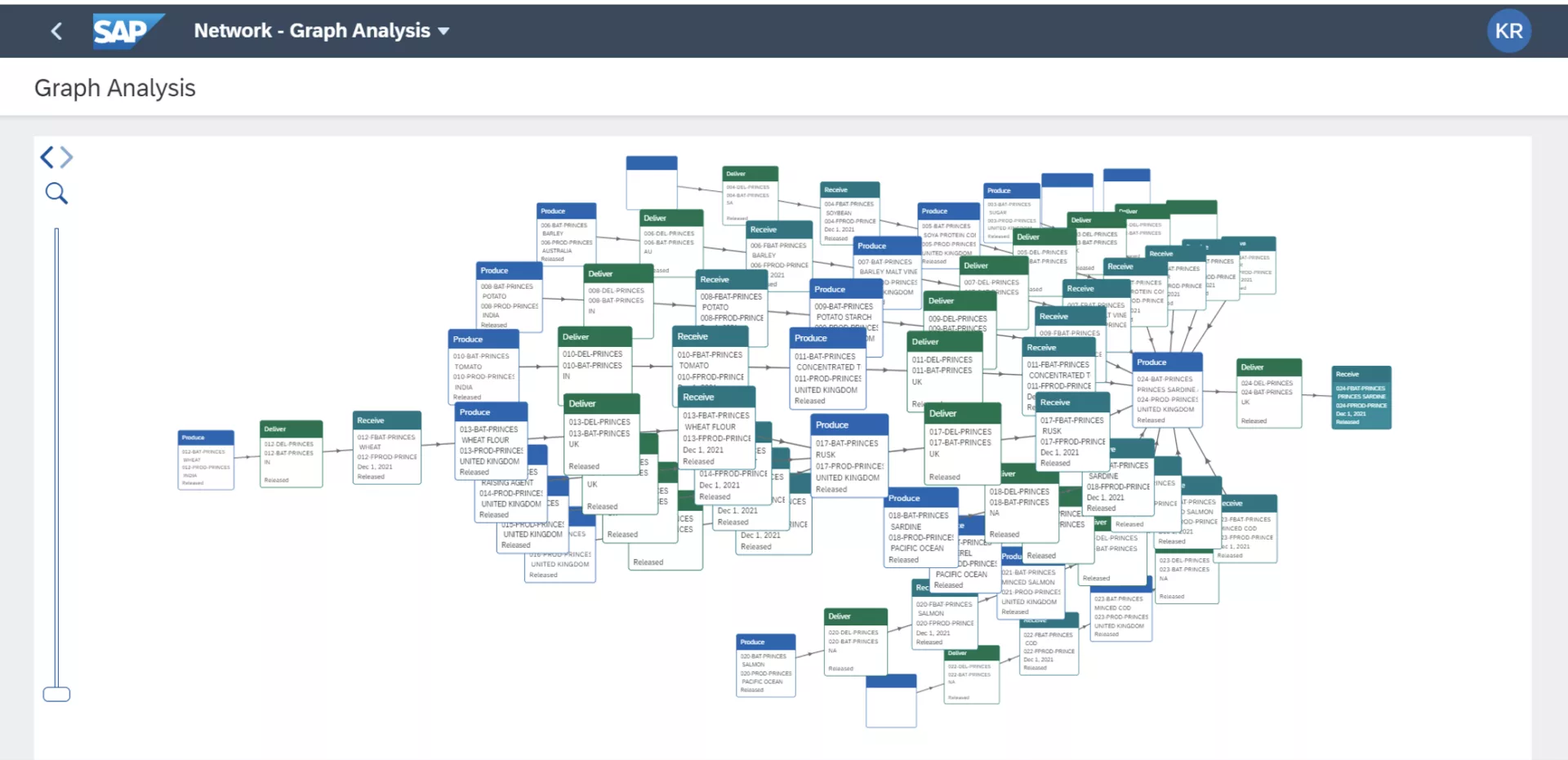

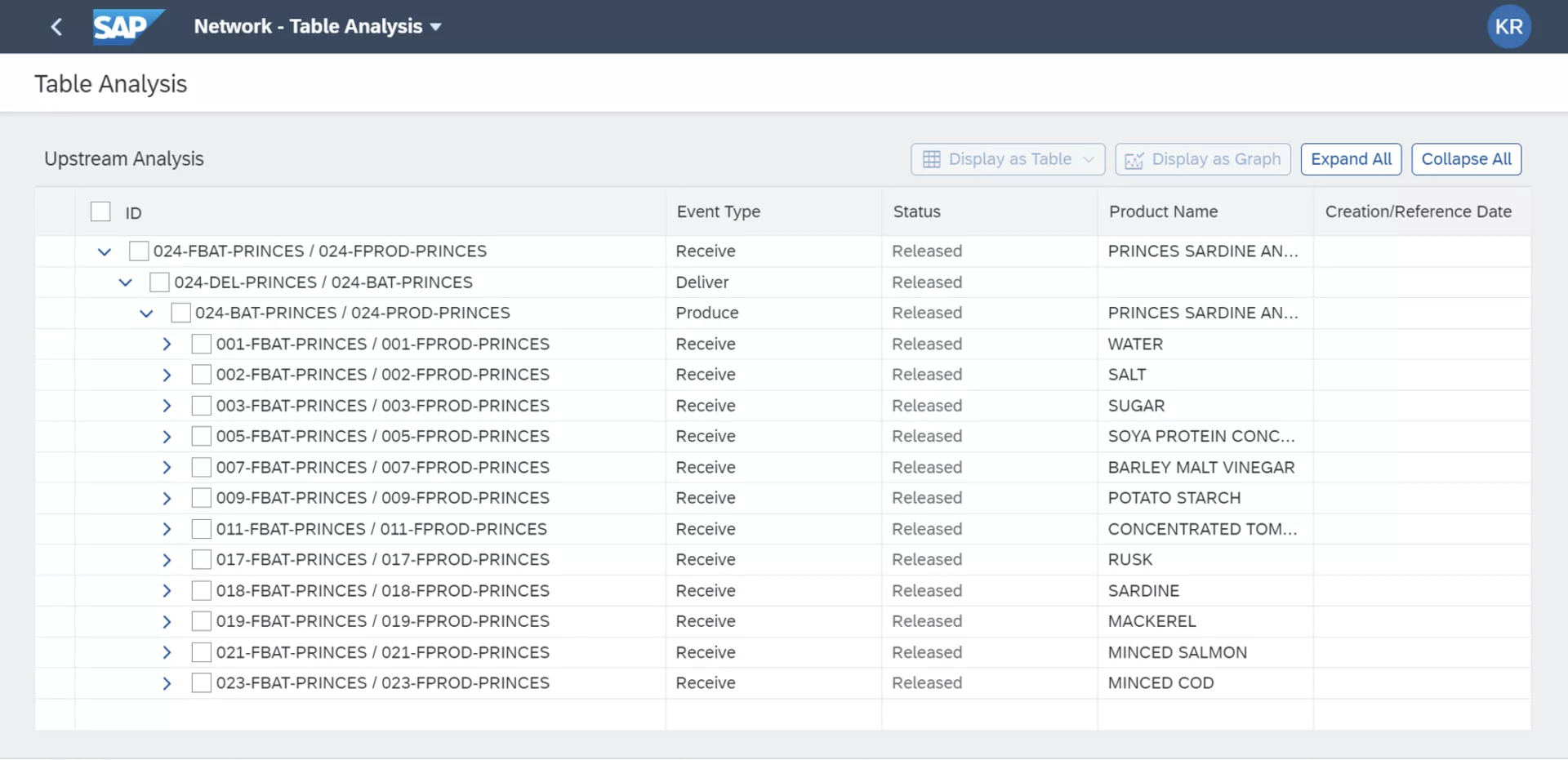

Genealogy analysis in material traceability allows businesses to track raw materials, components, and finished goods throughout their lifecycle using batch and serial number tracking. This ensures that organizations can monitor how raw materials are transformed into final products, which is essential for food production, the automotive, and pharmaceutical industries.

Genealogy analysis can be performed in two ways:

1.Graph View:

Provides a visual representation of material flow, making it easier to trace relationships between batches and serialized products.

2. Table View (Upstream & Downstream):

By leveraging genealogy analysis, businesses can:

Implementing SAP Business Network Material Traceability involves a few essential steps to ensure seamless tracking and compliance within the supply chain. The setup process includes:

With these steps, businesses can enhance visibility, improve compliance, and streamline material tracking across their supply chain.

Material traceability plays a crucial role in modern supply chain management, enabling organizations to enhance compliance, mitigate risks, and improve transparency.

SAP BN4L - Material Traceability offers a comprehensive solution to monitor materials from their origin to the final product, ensuring quality, efficiency, and adherence to regulations. As industries evolve, adopting robust traceability systems becomes crucial for optimizing operations and building consumer trust.

As a manufacturer/producer looking to earn your customers' trust, it's time to unlock the full potential of material traceability! ArchLynk is your trusted partner, offering end-to-end solutions from seamless implementation to full-scale integration. Connect with us for a demo today and see how ArchLynk can transform your supply chain!