The Transportation Load Building (TLB) is a feature of the IBP Response & Supply Planning module (Order-based planning) and has been released with the 2208 IBP Update.

It groups planned distribution receipts on the same transportation lane & delivery date into transportation loads, selecting the optimal equipment type based on cost. To use TLB, a planning area must be created using the SAP7F template (Order-Based Planning Based on Flexible Master Data).

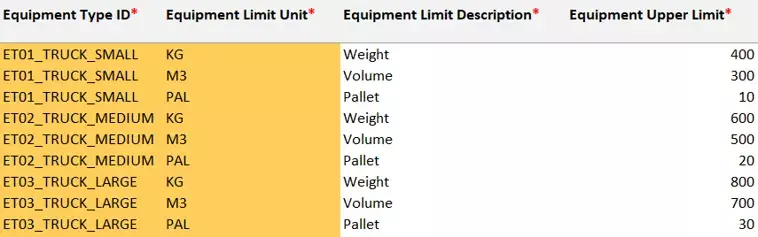

In IBP, the limits on resources are set through attributes within the master data type “Equipment Type Limit”, unlike in APO where this is done with profiles.

1.) Equipment Type: Defines available transportation resources in the supply chain.

2.) Equipment Type Limit: It defines constraints on the transportation resources.

3.) Alternate Unit of Measure: It’s important to maintain conversion factors for the limit units defined on Equipment Type (For ex: weight (KG), volume (M3), and palette (PAL) in this case). When TLB runs, these factors are used to perform calculations internally to ensure loads generated are constrained based on the upper limits of “Equipment Types”.

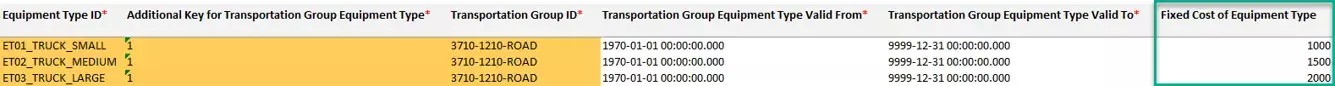

4.) Transportation Group: Represents an individual or group managing transportation resource(s)

5.) Transportation Group Equipment Type: This is the combination of two MDTs defined previously, namely, “Transportation Group” and “Equipment Type”. Cost of the available transportation resource(s) or Equipment type is defined within this MDT.

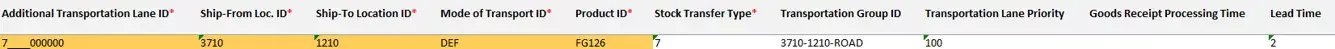

6.) Transportation Lane: This builds the association between “Ship-From Location” – “Ship-To Location” – “Product” – “Mode of Transport”. Also, the priority of the lane(s) can be set here within this MDT. When assigning transportation lanes to a transportation group – it’s important that the same values exist for “Ship-From Location”, “Ship-To Location”, “Mode of Transport”, and “Purchase Organization”. TLB run will not create loads for a transportation group if it includes lanes that violate this rule.

a.) Order-Based Planning: Transportation Load Building Run

b.) Order-Based Planning: Generate Planning Objects for External Key Figures

c.) Real-Time Integration (Outbound):

Pre-requisite for order integration between IBP/OBP and S4 or ECC system:

d.) Order-Based Planning: Unload or Delete Load Requisitions:

STR1 = 10000333, DD = 13.12.2022, Qty = 100

STR2 = 10000334, DD = 13.12.2022, Qty = 100

STR3 = 10000335, DD = 14.12.2022, Qty = 100

Step 1: STRs can be viewed in IBP “View Projected Stock” app:

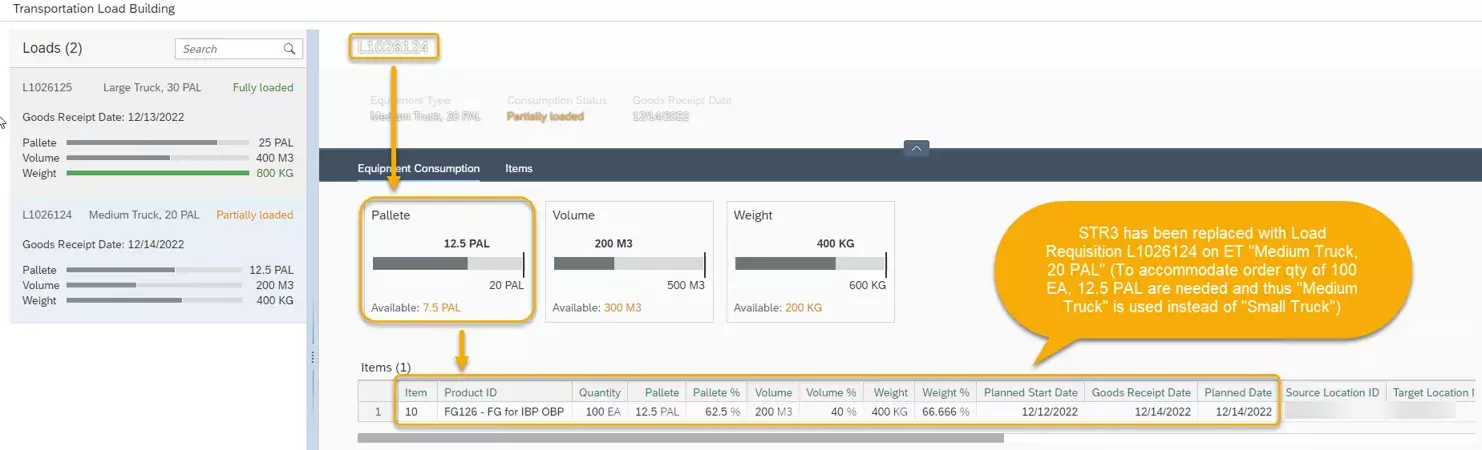

Step 2: Perform the TLB run, generate PLOBs for External KFs and view results in “Planner Workspace” app:

TLB component within “Planner Workspace” in IBP

TLB component within “Planner Workspace” in IBP

Step 3: Run RTI outbound to publish “Load Requisitions” from IBP to S/4