Companies work hard to drastically decrease transportation and logistics costs because of strong and certainly also innovative competition in their key markets. While customers demand increasingly accurate deliveries (time, location, quantities, quality), they try to optimize their resources and customer satisfaction. However, rising fuel costs, regulations, and decreasing capacity will harden cost savings much more. According to American Shipper Magazine research, in November 2013, 33 percent of the clients agree that optimization is a critical function for a global management system. In this article, we will concentrate on route optimization, which is a fundamental element of transportation optimization.

Basically, transportation route optimization is solving a mathematical problem with respect to the transportation network, resources, special constraints, costs, etc. There is no panacea for this kind of problem but to find the closest approach to the issue.

An American Shipper Magazine research, in November 2013, also implies that 23 percent of the clients are using manual methods to solve optimization. It is certain that automated optimization will handle the issue much more efficiently.

Introduction

In the logistics field, everyday planning can be complex and consumes manpower if done manually. One may need to consolidate each sales order, maximize the utilization of the vehicles and plan the best route while satisfying the demanding customer for fast delivery.

SAP TM uses its unique optimizer to solve transportation problems accurately and effectively. Even complex transportation problems can be solved with the SAP TM route optimizer with a proper configuration.

Features

SAP TM optimizer uses multiple parameters to get the best result. Location information, transportation network, delivery schedules, and resources that are used to execute the transportation are the basic parameters in optimizing. Special conditions such as transporting dangerous products or configuring compatible products to specific vehicles can also be defined in the system.

Generally speaking, SAP TM optimizer works to find the lowest cost for the transportation problem. However, the optimizer can be configured to use different criteria such as the cost for lateness or earliness.

Optimizer runtimes can also be configured to shorten the calculations, but it is better to keep in mind that the longer the optimizer runs, the better results it will get.

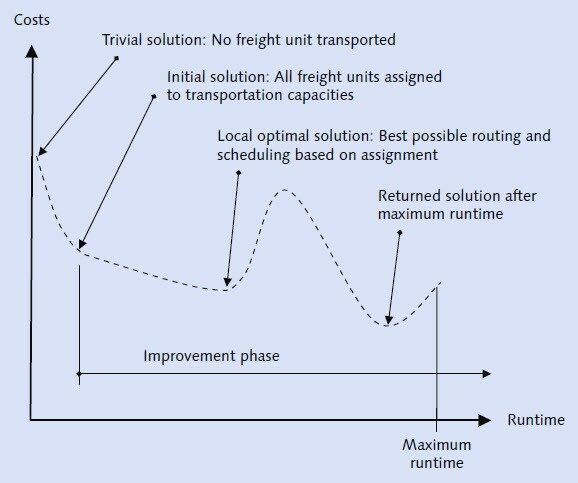

There are four phases SAP TM’s optimizer runtime behavior can be summarized below:

*Freight Unit: Smallest unit that can be transported together.

Generally, SAP TM first creates the models for the solution and gathers all data that is required. The Initial solution will include basic plannings that can also be found in manual planning. In the improvement phase, the local optimal solution and the best optimal solution can be found after a full optimization run.

Optimizer run can be configured through optimization configuration to receive the best quality, best speed, or balanced results.

Strategies

There are two types of strategies in SAP TM. By default, VSR_DEF (Vehicle Scheduling and Routing Default) strategy will be used to optimize the inputs. However, carrier selection optimizing will not be executed in the VSR_DEF strategy. The second option is the VSR_1STEP strategy. Carrier selection will be enabled if a VSR_1STEP strategy is chosen after running standard VSR.

VSR strategy consists of several subsystems like TVSR (Vehicle Scheduling and Routing Engine) and TVSS (Vehicle Scheduling Engine) which use the same framework.

An Optimization configuration screenshot can be found below:

SAP TM Optimizer may run for hours to execute the optimization, depending on the configuration. Since time is very crucial, some configurations should be considered to focus on the use case to either provide results with less complex settings, shorter run time, or for a complete replanning, considering all complexity.

Dividing the problem into sub-problems will affect optimization run in a good way. For instance, 1 means of transport with 50 locations will combine 2500 locations pair. However, if one can divide the problem into 5 sub-problems with 10 locations each; the result can be calculated as 5*10*10 = 500, which is only 20 percent of the total possibilities. The consultant must work with the planning team to split problems into independent sub-problems. Generally speaking, these subproblems can be classified as geography (region), product group (frozen, non-frozen, etc), time horizon (planning for a few days or a week at most), or FTL, LTL, FCL, LCL scenarios. Still, the optimizer itself leverages opportunities to cluster a subset of data based on common characteristics of relevant freight units, etc.

The number of means of transport is a very basic parameter for the optimizer, therefore, has a huge impact. Each means of transport will create additional alternatives, therefore, decreasing performance, especially with respect to memory consumption. Since each means of transport will store the information of transportation lane, which is the main cost for the memory, reducing means of transport is quite important for the performance.

Lanes are used to describe distances between the locations. Only available and necessary lanes should be maintained to receive better results, based on the given requirements. If there are multiple locations in the same area, zone creation can be used in order to decrease data and calculations.

Reference coordinates can also be used to define locations. In long distances, nearby locations can be defined in the same reference coordinate as in zone logic. The key point here is storing the reference coordinate in a central location which is more or less to indicate several locations. GIS integration will be needed to retrieve exact coordinates.

Incompatibilities may be used to limit certain conditions or data selections that can be input to the optimizer – the optimization problem. For example, it can be used to prevent the assignment of freight units to certain resources or to use transshipment locations. If used to reduce the number of resources, each incompatibility will increase the performance of the optimizer.